What Is SBR Rubber?

SBR (Styrene Butadiene Rubber) is a synthetic rubber copolymer made from styrene and butadiene, offering excellent abrasion resistance, durability, and flexibility. Widely used in automotive, construction, and industrial applications, SBR rubber is a cost-effective alternative to natural rubber with superior performance in various environments.

Key Benefits of SBR Compound

Superior Durability & Flexibility

The SBR compound provides outstanding resistance to wear, making it ideal for tires, gaskets, and seals. Its styrene butadiene copolymer structure ensures long-lasting performance under stress.

Excellent Water & Chemical Resistance

SBR rubber sheets are widely used in waterproofing applications due to their resistance to moisture, oils, and chemicals. This makes them perfect for SBR gasket manufacturing and industrial sealing solutions.

Cost-Effective Material

Compared to natural rubber, SBR rubber price is more affordable while maintaining high performance. This makes styrene butadiene rubber a preferred choice for budget-conscious industries.

Applications of SBR Rubber

Automotive Industry (SBR Automotive)

Tires & treads – Enhances grip and durability.

Hoses & belts – Resists heat and abrasion.

Vibration dampening components – Improves vehicle performance.

Industrial & Construction Uses

SBR rubber sheets for roofing and waterproofing.

Conveyor belts due to high wear resistance.

Footwear & adhesives for enhanced flexibility.

Specialized Uses (SBR Latex & Gaskets)

SBR latex is used in coatings, carpet backing, and paper processing.

Styrene butadiene rubber latex provides excellent binding properties.

SBR gasket materials ensure leak-proof sealing in machinery.

our Product Dimensions

Physical and chemical properties

Shore “A” hardness: 60-65

Tensile strength, minimal: 350 PSI

Elongation, minimal: 400 %

Temperature Range: -13 to 176 °F

Oils: Bad

Acids: Medium

Outdoors: Medium

Abrasion: Medium

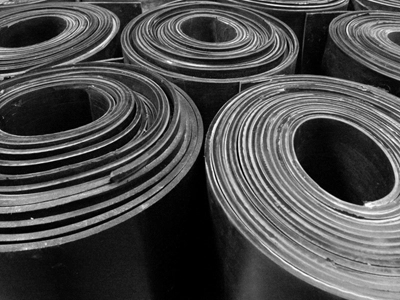

SBR Rubber sheets & rolls

Plate: 3'3" x 3'3", 1/16" to 3" thickness

Sheets: 3'3" x 32'9 " long, with 1/16" to 5/16" thickness

Sheets: 3'3" x 16'4" long, with 3/8" to 5/8" thickness

Why Choose Our SBR Rubber Products?

High-quality styrene butadiene styrene rubber (SBS) formulations.

Competitive styrene butadiene rubber price.

Custom SBR compound solutions for specific needs.

Durable SBR material for long-term industrial use.

Red SBR Rubber

Red SBR rubber in rolls and sheets is the most widely used rubber worldwide. Our red SBR roll is manufactured in a controlled environment free of contaminants, which is confirmed by the purity of its color. This ensures the best performance and compliance with the resistance standards defined for its use.

Red SBR rubber in rolls and sheets is an economically priced general purpose elastomer. Compound with high energy absorption factors ideal for absorbing sound, vibration and shaking. Modern construction technologies lead to the design of lighter and lighter structures, walls and slabs requiring vibration energy absorbing materials. Red SBR in rolls is the right material to be placed between slabs and walls to isolate footsteps and sounds in the range of 200 to 1500 hz.

Learn more about our acoustic rubber for floors.

Physical and chemical properties: Red SBR Rubber

Shore “A” hardness: 70-75

Tensile strength, minimal: 500 PSI

Elongation, minimal: 300 %

Temperature Range: -13 to 176 °F

Oils: Bad

Acids: Medium

Outdoors: Medium

Abrasion: Medium

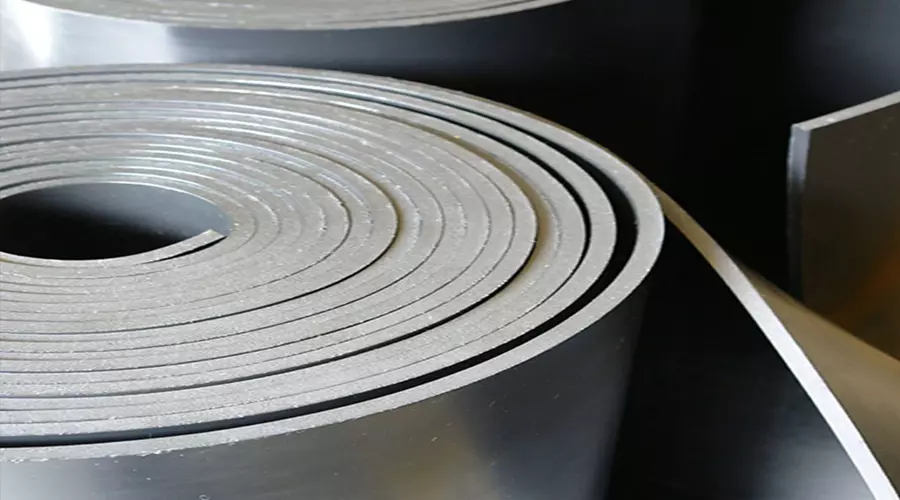

SBR Rubber sheets & rolls

Plate: 3'3" x 3'3", 1/16" to 3" thickness

Sheets: 3'3" x 32'9 " long, with 1/16" to 5/16" thickness

Sheets: 3'3" x 16'4" long, with 3/8" to 5/8" thickness

Applications and characteristics of SBR Red

- Excellent for vibration, trepidation and sound isolation in adjacent structures.

- Good for flanges, gaskets, conveyor belt sidewalls, supports, shock absorbers and all types of rubber applications where elasticity is required at low cost.

- Its WATERPROOFING characteristics make it especially useful to stop water seepage between floors and walls.

- It requires reinforcing loads to achieve good mechanical properties and abrasion resistance can be achieved that is superior to that of NR.

- It has similar properties to NR, but with greater resistance to aging and temperature and, as with NR, its resistance can be increased with the appropriate formulation.

- Red SBR is clearly inferior in terms of resilience compared to natural rubber.

Looking for Reliable SBR Rubber Suppliers?

Whether you need SBR rubber sheets, SBR automotive parts, or styrene butadiene copolymer solutions, we provide top-grade materials at the best SBR rubber price. Contact us today for high-performance styrene butadiene styrene polymer products tailored to your requirements!

We have a wide variety of rubber types, visit our rubber materials page.