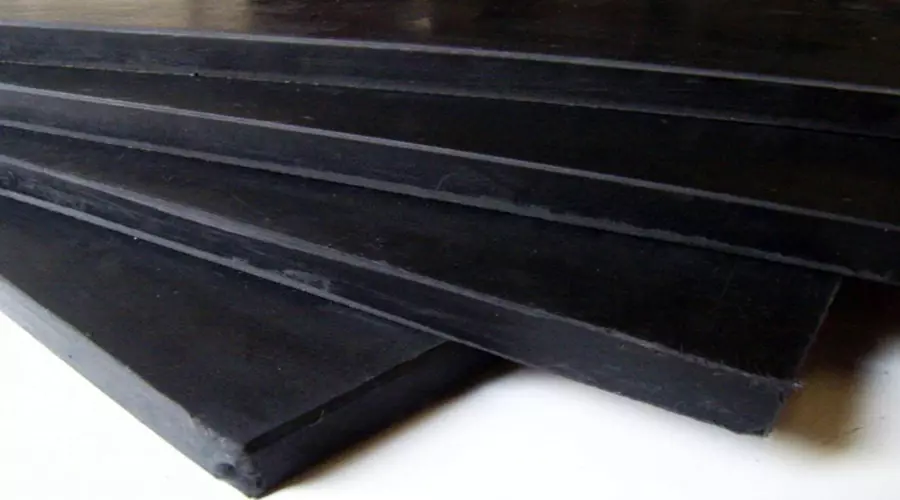

Hypalon Rubber

Hypalon in roll and sheet form is a chlorosulfated synthetic polyethylene rubber with high resistance to chemicals and extreme temperatures, as well as oils, and is used in a wide range of applications including automotive and high performance industrial applications.

Ideal gasket to manufacture flanges or seals in the chemical process industry, extraordinary aging-resistance due to weather exposure and heat, not affected by sunlight and outdoor exposure.

What is hypalon rubber?

Hypalon in rolls and sheets. Hypalon is a synthetic rubber, product of the chlorosulfonation reaction of polyethylene. Its international abbreviation is CSM (Chlor Sulfonated Methylene).

CSM rubbers have excellent resistance to oxidation, weathering and ozone, with extraordinary color fastness, precisely for this reason inflatable boats are manufactured with this material.

Hypalon rubber properties:

- Shore “A” hardness: 60-65

- Tensile strength, minimal: 1200 PSI

- Elongation, minimal: 430 %

- Temperature Range: -13°F a 329°F

- Oils: Good

- Acids: Excellent

- Outdoors: Excellent

- Abrasion: Good

The ideal gasket for manufacturing flanges or gaskets in the chemical processing industry, outstanding resistance to weathering and heat aging, unaffected by sunlight. Resistant to strong acids and bases and to a wide variety of chemicals.

Product Dimensions:

- Plate: 3'3" x 3'3", 1/16" to 1" thickness

- Sheets: 3'3" x 32'9 " long, with 1/16" to 1/4" thickness

Hypalon rubber sheet characteristics:

- Impermeable to water and acids.

- Excellent aging.

- Very good resistance to hydrocarbon solvents.

- Good flame resistance and self-extinguishing.

- Resistant to most inorganic chemicals, except chlorine, concentrated acids and oxidizers.

- Moderate resistance to aliphatic and aromatic hydrocarbons.

Hypalon rubber applications

- The construction industry or in the electrical industry for its waterproofing capacity.

- Sealing gaskets against chemical agents in flanges, fittings, plates, doors, etc.

- Protections and coatings of equipment in chemical or automotive industries.

- Applications requiring a rubber that resists up to 135°C and with good flame resistance.

- Expansion joints.

Hypalon rubber chemical resistance:

It is generally recommended for applications with strong acids, freons, hydroxides, ozone, alcohols, and alkaline solutions as well as sodium hypochlorite.

Hypalon in roll and sheet form is a chlorosulfated synthetic polyethylene rubber with high resistance to chemicals and extreme temperatures, as well as oils, and is used in a wide range of applications including automotive and high performance industrial applications.