Acoustic Insulation for Walls and Floors

The acoustic insulation for walls, is one of the materials to isolate the noise and is designed to absorb and eliminate the noise that is produced when working, training or to isolate an enclosure or house from both external and internal noise.

Our acoustic insulation is a mixture of sound insulating materials, capable of drastically isolating noise and sound vibration in a room or building, its use is very varied and can work very well in a boardroom, a television room, an auditorium, an office, or anywhere where noise reduction from the outside is sought.

Acustic insulation for walls, floors and ceilings. Thanks to its sound insulating properties with high quality finish, it is the best choice in acoustic insulation.

Applications of acoustical insulation:

- Hotel room noise isolator

- Thermal and acoustic insulation for heating systems

- Acoustical insulation for walls in elevator installations

- Noise insulation for conference room walls

- Noise insulation panels for movie theaters

- Sound insulation for concert venues

- Acoustic insulation in walls and ceilings of buildings or commercial premises

- Sound-insulating materials in airport lounges

- Noise insulation for walls in areas where vibration-emitting machines are in operation

Rubber product: Acoustical insulation for Walls and Floors

- Presentation: roll of acoustic insulation

Roll of acoustic rubber of 1m x 10 linear meters.

| PARAMETERS | METHODS | SPECIFICATIONS |

|---|---|---|

| HARDNESS, SHORE A | ASTM-‐D2240 | 60 – 65 |

| TENSILE STRENGTH, psi | ASTM-‐D412 | 550 MINIMUM |

| % ELONGATION | ASTM-‐D412 | 400 MINIMUM |

| TEAR STRENGTH,KN/m | ASTM-‐D624 | 16 MINIMUM |

| TEMPERATURE RANGE, (CENTIGRADE) | ASTM-‐D573 | 25°C to 90°C |

| ABSORPTION OF VIBRATION | EXCELLENT | |

| SHOCK ABSORPTION | EXCELLENT | |

| Composition: high density polymer compound. | ||

| Acoustic properties: | Sound attenuation 45 db |

Sale of noise insulation

If you are looking to buy acoustic insulation, we offer acoustic insulation rubber rolls. Silenziotec is a floor and wall insulation with excellent benefits in commercial applications, such as hotels, motels, gyms, dance schools, conference rooms, condominiums and also in residential applications. It contributes to the increase of the acoustic performance of the slab, reducing noise by vibration transfer between one space and another.

Recommendations for proper soundproofing with acoustic insulation for walls

- To know the type of acoustic rubber to choose the best one according to the location, type of construction and orientation of the building.

- Determine the humidity of the wall or floor where it is placed, and recognize if the weight of the material can withstand the surface.

- Select among the different thicknesses and sizes of the sheets to be used, in addition to verifying the size of the insulating rubber, which can be flexible and in rolls.

- Fasten with special adhesives to ensure the durability of the acoustic insulation.

- Establish the intended frequency level to choose the elements that will mitigate the sounds, seeking advice from professionals to get the density of the product right.

There are many more acoustic insulators on the market, if you need specialized advice to choose the best acoustic rubber...

Contact us without obligation!

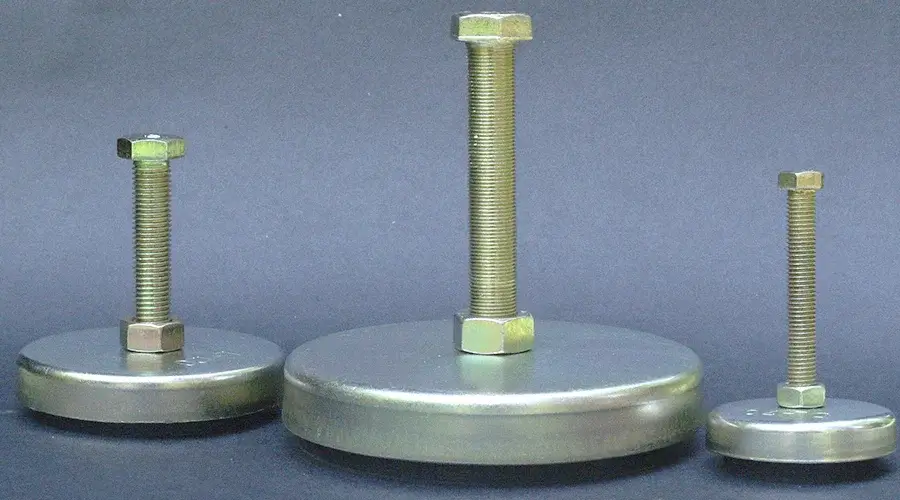

Vibration isolator what is it?

Vibration isolation is the process of isolating an object, such as a piece of equipment, from the source of vibrations.

It is defined as a device that reflects and absorbs oscillatory energy waves, extending from a piece of working machinery or electrical equipment, and whose desired effect is vibration isolation. The objective is to establish vibration isolation between a body transferring mechanical fluctuations and a supporting body (e.g. between the machine and the foundation).

It is now possible to control unwanted vibration and compensate for floor irregularities, with one device.*

The elastomer element of the vibration leveler is resistant to oil and chemical agents. Its lifecycle is practically wear free, its metal component is treated to assure a long life cycle.

No fillers (flecha) Unaffected by weather, chemicals, grease and oil

No anchoring (flecha) Lower installation cost.

Unaffected by weather, chemicals, grease and oil. (flecha). Zero maintenance cost.

Product Dimensions

| MODEL | MEASUREMENTS IN MM | MAXIMUM LOAD | ||

|---|---|---|---|---|

| D | A | D SCREW | Lbs | |

| DL-70 | 70 | 24 | 11 | 555.5 |

| L-120 | 110 | 31 | 16 | 2888.8 |

| L-160 | 160 | 40 | 19 | 7777.7 |

| L-200 | 208 | 45 | 25.4 | 13333.3 |

* Vibration Isolators, absorb height difference between the equipment’s supports. Still, it is important to note that the support surface on which the vibrating levelers rest should be completely horizontal.

Recommended Uses

- Lathes

- Mills.

- Grinding machines

- Presses

- Stampers

- Plastic and rubber injection machines

Do you wish to relocate your equipment?… just lift it and move it... That's it! Vibration Isolators, reengineering's great helper.