Fluorosilicone O-Rings Rubber

The primary use of fluorosilicone is in fuel systems at temperatures up to 220°C and in applications where the dry-heat resistance of silicone is required but the material may be exposed to petroleum oils and/or hydrocarbon fuels.

Our engineering department has developed the polymer with maximum ability to withstand low temperatures

in contact with oil preserving its sealing properties.

FLUOROSILICON BASED COMPOUND

Everest Fluorosilicone O-rings are in stock for immediate shipment. Leverage direct purchasing power from the world's largest O-ring inventory network for fast shipping, low prices and reliable service.

What is fluorosilicone?

Fluorosilicone o-rings are a hybrid of silicone and FKM resulting in great jet fuel resistance with high and low temperature performance. Also widely used in semiconductor Ashing equipment with strong resistance to oxygen plasma, FVMQ fluorosilicone o-rings also feature excellent flexibility, compression resistance, aging and sunlight resistance, and overall wide range of basic chemical resistance.

Fluorosilicone elastomer seals also offer an outstanding resistance to ozone, sunlight and weathering, which makes it the perfect compound to use within aviation. Although generally specified for aerospace use, fluorosilicone is also becoming an increasingly popular material for a wider range of sealing purposes.

For more than 50 years, Everest Rubber has been offering custom and standard o-rings and other sealing solutions for multiple industries. With millions of products produced and shipped annually, we are the experts your organization needs to seal the success of your application.

Physical Properties: Fluorosilicone O-Rings Rubber

| PARAMETERS | SPECIFICATIONS |

|---|---|

| Hardness, Shore A | 65 |

| Tensile Strength, PSI | 1500 Minimun |

| Maximum Elongation | 330 % |

| Tear Strength,N/Mm | 24.5 Minimun |

| Operating Temperature Range | -63°C to 220°C |

Mechanical And Operational Properties

| SUBSTANCES | SPECIFICATIONS |

|---|---|

| Aged In Air At 175°C | |

| Change In Hardness | +2 Points |

| Maximum Elongation | 330 % |

| Tear Strength,N/Mm | 24.5 Minimun |

| Operating Temperature Range | -63°C to 220°C |

Chemical Properties

| SUBSTANCES | SPECIFICATIONS |

|---|---|

| Immersion In Transformer Oil 70 Hrs At 100°C | |

| Change In Hardness | -1 Points |

| Volume Change | +0.65% |

| Change In Tensile Strength | -4.8% |

| Change In Elongation | -5% |

| Permanent Compression 22 Hrs At 100°C (ASTM 395) | |

| Permanent Compression 70 Hrs At 100°C | 6.35% |

Fluorosilicone O-ring Temperature Range:

The above temperature ranges are for dry air service only and should not be used to determine design specifications or end-use temperature limits. The actual temperature range of a joint in an end-use application is highly dependent on part type, hardware configuration, applied forces, chemical media, pressure and temperature cycling effects, and other factors. The most practical way to determine the end-use temperature range is to test under actual use conditions.

Features and Durability of Fluorosilicone O-Rings:

- Excellent flexibility and resistance to compression set

- Excellent aging and weather resistance

- Resistance to oxidative chemicals, animal and vegetable oils, fuels, aromatic and chlorinated solvents

- Resistant to dilute alkalis, diester oils, aliphatic and aromatic fluorocarbons, silicone oils, toluene, benzene, ozone and oxidizing environments.

Fluorosilicone o-rings limitations :

- - Brake fluids, ketones, hydrazine, adelhydes, amines, ketones

- - Poor abrasion resistance

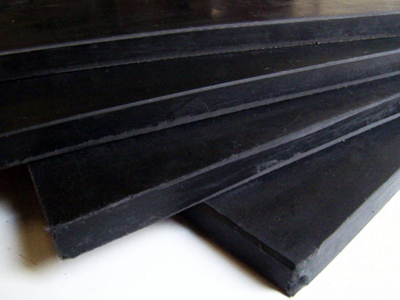

FLUOROSILICON BASED COMPOUND